It’s easy to be bitter and refer to my tequila/cheaterquila as the cursed batch. You may remember that we started this party on July 28. It’s been the better part of 3 months and it’s still in the fermenter. Adding insult to injury, it has not yet hit my initial ABV goal. Some of my frustration has certainly been that progress is slow, but most of it is more or less directly related to the fact that approaching my hobbies is different with a more demanding career and two smallish children. Coming up with the spare cycles to manage the extra load has been frustrating. However, that doesn’t mean that the experience has been all together bad. Quite the opposite. I’m feeling pretty good about things.

First, I did final measurements last night. We’re at about 7.7 percent ABV with a FG of about 1.056 (down from OG 1.115). The refractometer is counting on it being a bit warmer than it is in my basement. I’m hoping that this bumps the yield up slightly. That should give us a bit over a half gallon of ethanol (7 gal * .077). It’ll be less when we cut the garbage out, but it’s not a terrible place to start. If I can do the run today, and that’s an “if” because my darling wife has tested positive for covid. I’m not sure I’ll be able to sneak away. I’ll keep you posted one way or the other.

But…what have we learned? Surely my frustration and fury has yielded something tangible. Moving forward from this batch I can see there’s room for improvement on a few things.

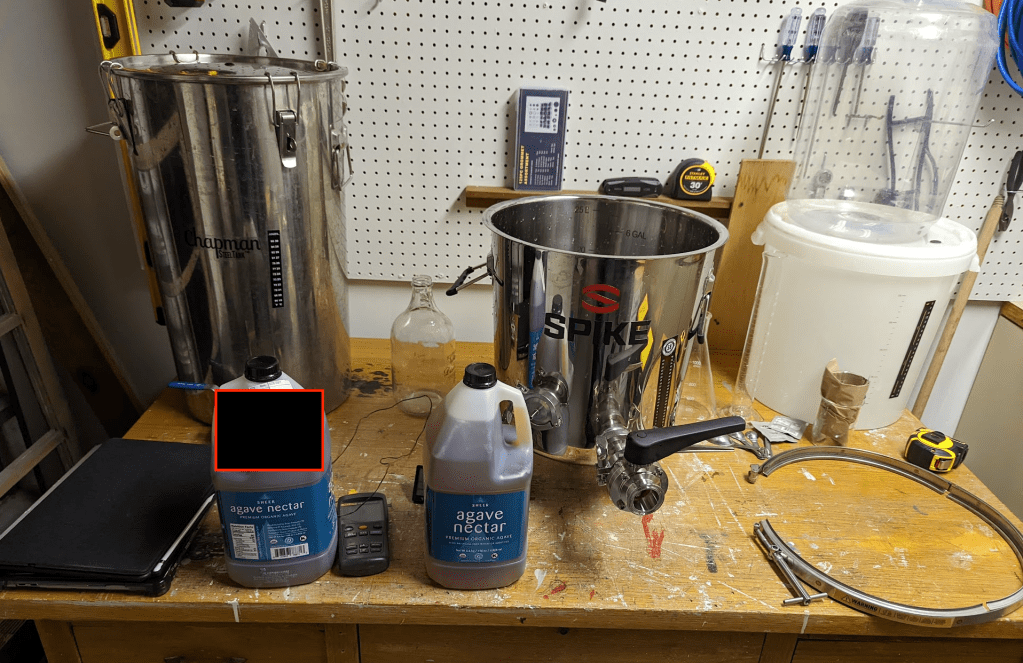

- I need to look into temperature control for the fermenters. I live in Canada, and my basement is too damn cold. In the fall it’s chilly because, well, Canada. At the end of summer it’s chilly because we’re actually running the air conditioner and all that condensed air just sits in the basement. Spike has a solution and I need to pick it up before I try again. I should also look into something for the Chapman as well.

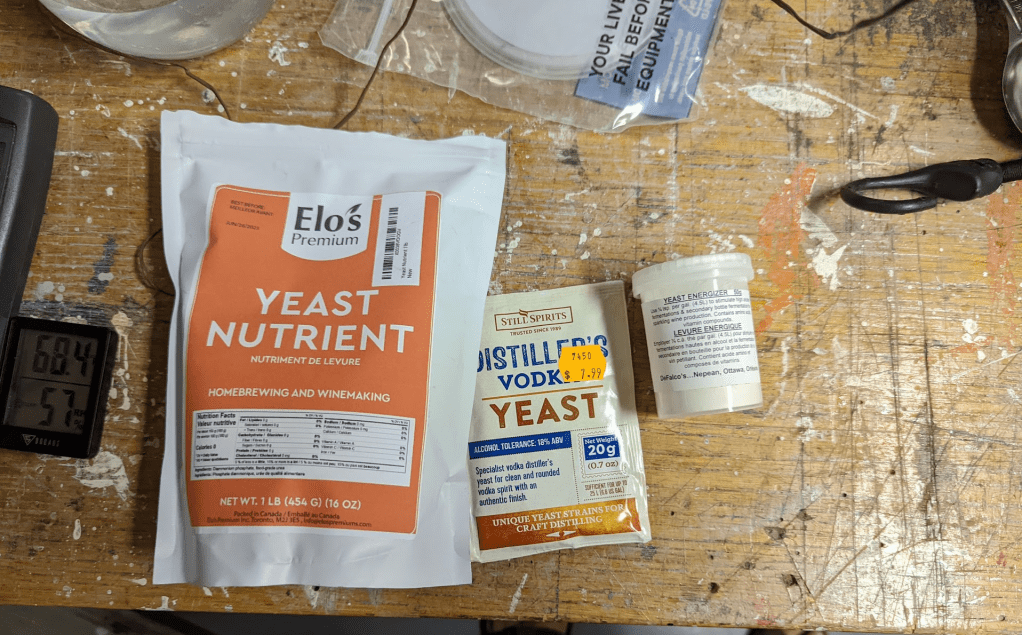

- Buy some fucking fermaid. I have been using ELO and some yeast energizer, but apparently fermaid K or O (pref O since I’m an organic loving yuppy) will help me get more out of my yeast (allegedly).

- Did I mention temperature? I think consistency is important. During the past few months I’ve been away from home for several weeks. With the colder (high/mid 60s F) temperature in the basement that means that fermentation has just done nothing for the better part of a month during the past few months.

- I’m still learning. It’s important to mention this, because I tend to have an over inflated sense of my own knowledge. Just ask me, I’ll tell you how I know everything. This batch represented a tremendous learning experience. First time without turbo yeast, first time with agave, first time with the new fermenter, first time with yeast nutrients and on, and on.

All things considered, I’m feeling good about it. I’m ready to move on to the distillation, polishing and aging. Let’s do it!